Headset parts printing processing

Product Description

Digital products printing processing

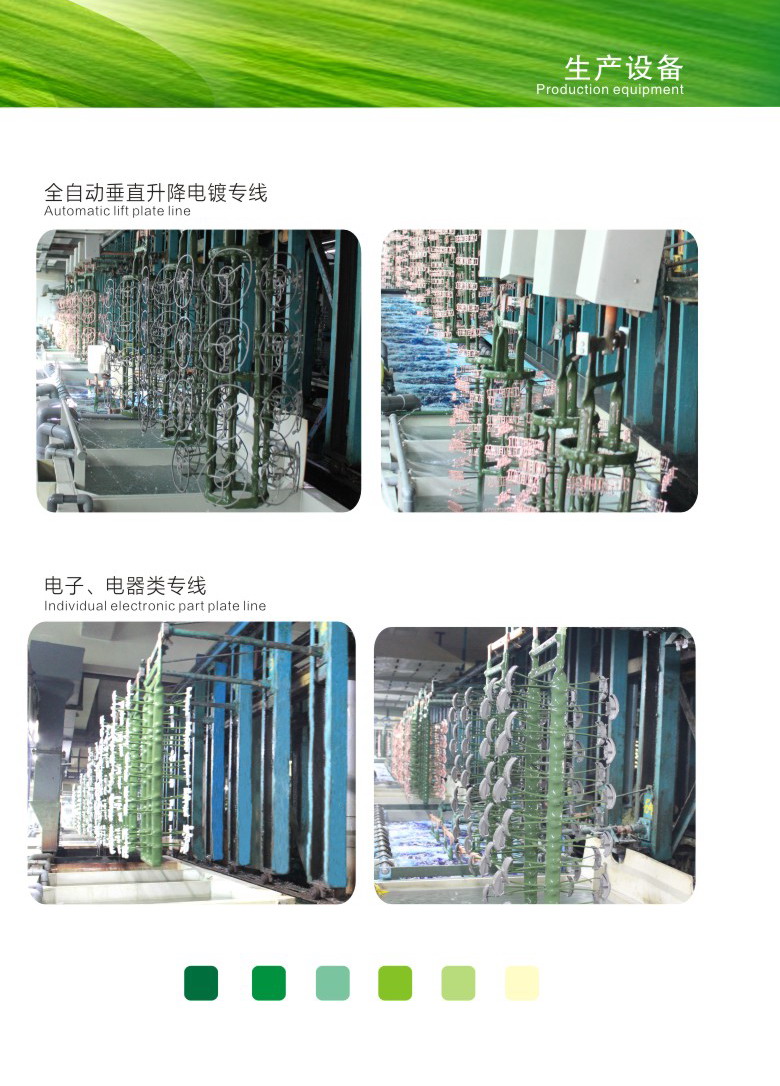

Screen printing is based on the original, plate-making method and the choice of printing process, and decided to use printed materials. Since the use of silk screen is very extensive, so there are many types of corresponding processes, which is very important to work. The materials used in the various processes are also different, depending on the nature of the pattern, the amount of replication, the use of the product, and the choice of what kind of material to use. For example, the screen is now more than the use of nylon, polyester, stainless steel, its performance is different. Such as nylon mesh with the ideal flexibility and elasticity, as well as convex and convex surface printing characteristics. In the requirements of high-precision printing, the use of Stainless Steel Wire Mesh. In addition, according to different patterns, you can also take the tension of the oblique method, so that the latitude and longitude of the cable and the direction of the scraper to maintain a certain angle, but also allows the network to allow tension in the case of tension, relax.

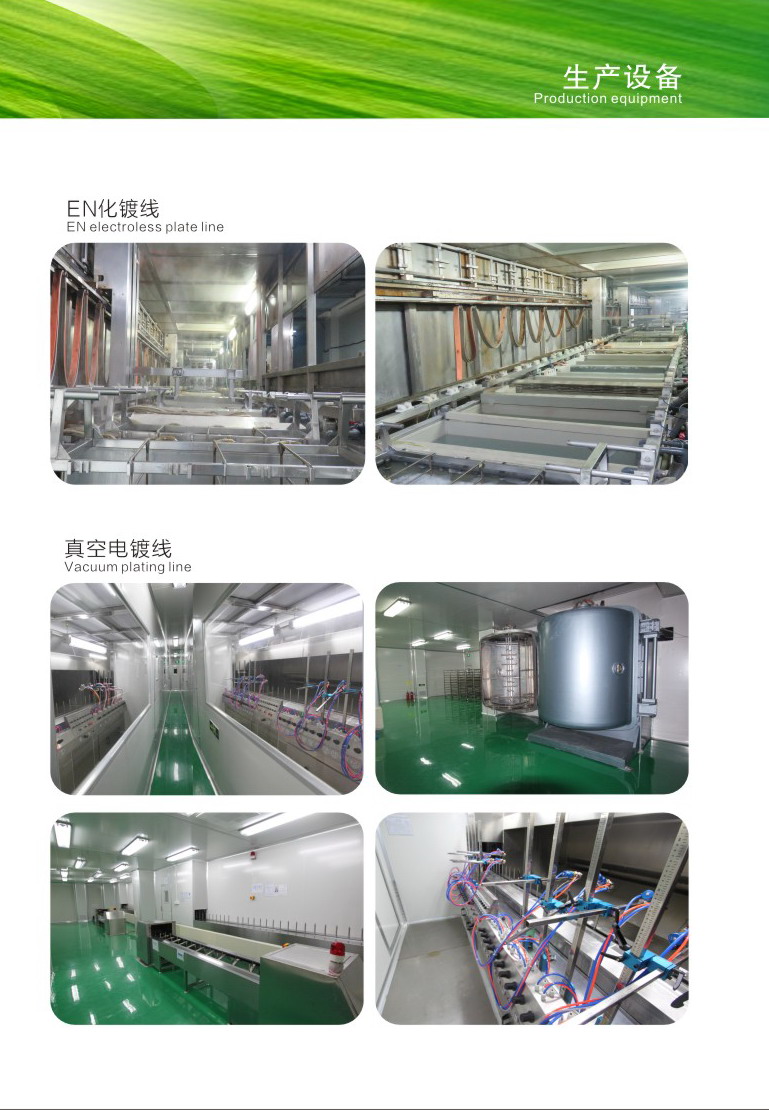

Jinyuan Kang company has developed a new automatic drawing with the effect of ABS plastic coating surface treatment process, the traditional drawing process is carried out in the metal material, manual manual operation, the process will be dust hazards, and product quality is not Stability, lines can not be maintained, a waste of human and material resources.

The company is now drawing the drawing is in the plastic coating surface drawing, the surface effect can replace the metal texture, but also the use of machines instead of manual operation, reduce dust and other hazards%. Drawing products are not too strong reflective, will not stimulate the eyes.

(2) for car parts have a good safety performance;

(3) wire drawing of the twist can be fine, and lines;

(4) drawing stripes neatly have a strong metallic texture;

Product Categories : Printing Process > Screen Printing Process